After strapping myself into my new seat, and pulling the shoulder harnesses tight, I noticed one thing... I have to stretch to reach 1st, 3rd, and 5th gear. Fine for autocross when I'm in 2nd gear the entire time, but for open tracking when 2nd through 4th are typically used (or when just driving around on the street for that matter), this wasn't going to work.

Solution? My latest project:

Remote shifter...ScotWithOne_t style.

I started out just wanting to just build some sort of spacer to mount the stock shift lever on, moving it back and to the left a couple inches. This works, but also increases the overall length of the lever, meaning an even longer throw.

Back to the drawing board.

I did some research online for custom shifters, and found a plethora of stock style short throw shifters, but nothing that relocated the actual shift linkage. MGW makes a custom shifter that is adjustable up, down, and radially, but this still wasn't good enough. A little more research led me to corner-carvers, and I found out that what I really needed was a "remote shifter". To my knowledge, only one company makes one (link), but there is two problems with it…well…three. First, it is designed for a first gen Mustang with a T5, so the linkage would be too long for my application. Secondly, I just really don't like the design of it. It looks pretty, but the bolt holding the flat machined part of the shaft against the shifter stub is also acting as the pin for thrust, AND as the element that bears the moment from moving the stick side to side. Thirdly (and for those of you that know me, most obviously), it cost $200.

So I set out to design my own remote shifter. I tried to come up with some geometry to reduce the throw, but I determined that it is impossible without it binding up when you move it side to side. So I'm stuck with the stock throw, but in a better location. That can always be fixed later on with a short throw shifter with positive stops (which I should get eventually anyway). My design makes use of 1/4" X 1" steel flat bar, nuts and bolts, and one 1/4" heim-joint. Using one piece of flat bar sandwiched between two other pieces, and a 3/8" bolt through them, I am able to get fairly slop free thrust, a rigid moment, and since the two outside pieces of flat bar are spaced with another small piece of flat bar, the joint spins easily even when the bolt is tight.

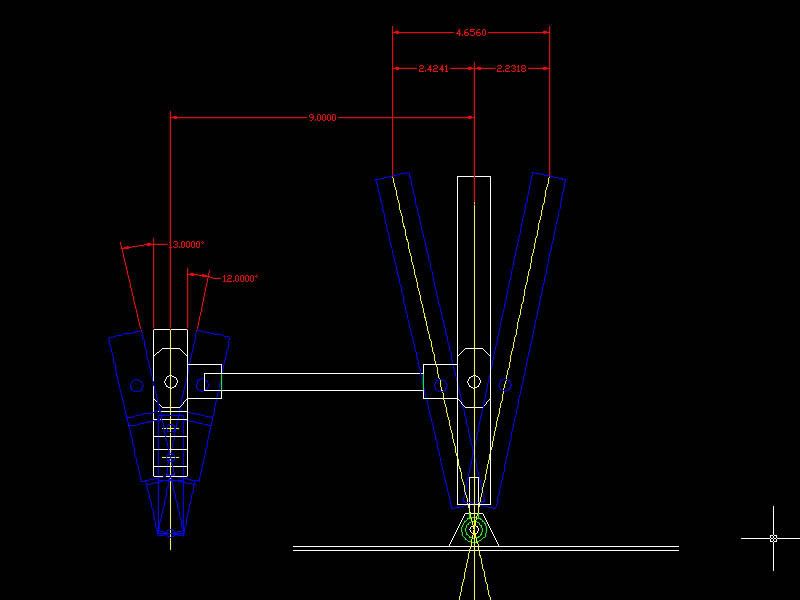

Here is the concept sketch:

The throw should actually be slightly less than stock, since the total lever length is slightly less than the effective length of the funky shaped stock lever.

I'm about half done. Had to stop because the bolts that hold the stock lever on are not long enough. I thought they were standard 5/16" bolts, but they must be metric. The thread pattern matches a 1/4-20 bolt, but it is 5/16" diameter. Going to have to swing by the hardware store tomorrow to get new bolts. I also have to figure out how I will mount a shift ball to the top of it. I'll probably end up cutting the flat bar just above where the linkage connects to it, and welding on some of the same 1/2" tubing to the top that I used for the horizontal link, just to pretty it up some.

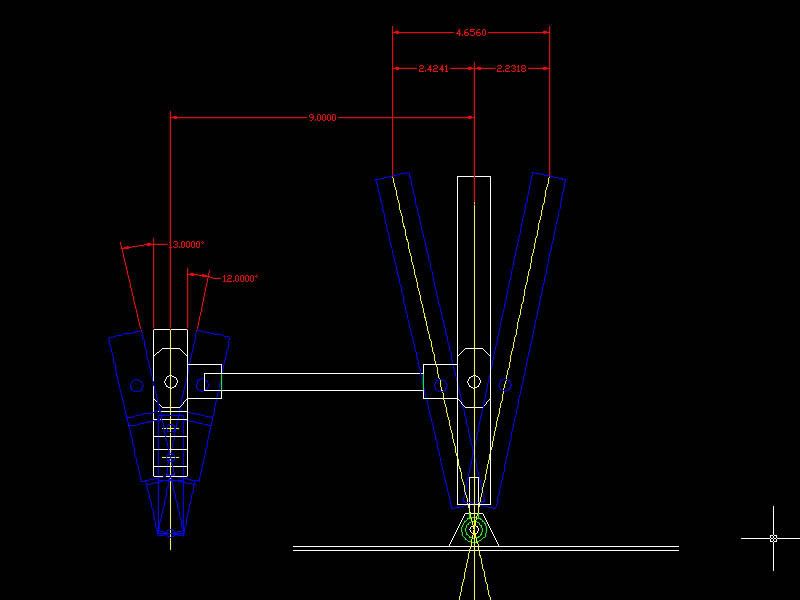

Here is the progress so far:

Solution? My latest project:

Remote shifter...ScotWithOne_t style.

I started out just wanting to just build some sort of spacer to mount the stock shift lever on, moving it back and to the left a couple inches. This works, but also increases the overall length of the lever, meaning an even longer throw.

Back to the drawing board.

I did some research online for custom shifters, and found a plethora of stock style short throw shifters, but nothing that relocated the actual shift linkage. MGW makes a custom shifter that is adjustable up, down, and radially, but this still wasn't good enough. A little more research led me to corner-carvers, and I found out that what I really needed was a "remote shifter". To my knowledge, only one company makes one (link), but there is two problems with it…well…three. First, it is designed for a first gen Mustang with a T5, so the linkage would be too long for my application. Secondly, I just really don't like the design of it. It looks pretty, but the bolt holding the flat machined part of the shaft against the shifter stub is also acting as the pin for thrust, AND as the element that bears the moment from moving the stick side to side. Thirdly (and for those of you that know me, most obviously), it cost $200.

So I set out to design my own remote shifter. I tried to come up with some geometry to reduce the throw, but I determined that it is impossible without it binding up when you move it side to side. So I'm stuck with the stock throw, but in a better location. That can always be fixed later on with a short throw shifter with positive stops (which I should get eventually anyway). My design makes use of 1/4" X 1" steel flat bar, nuts and bolts, and one 1/4" heim-joint. Using one piece of flat bar sandwiched between two other pieces, and a 3/8" bolt through them, I am able to get fairly slop free thrust, a rigid moment, and since the two outside pieces of flat bar are spaced with another small piece of flat bar, the joint spins easily even when the bolt is tight.

Here is the concept sketch:

The throw should actually be slightly less than stock, since the total lever length is slightly less than the effective length of the funky shaped stock lever.

I'm about half done. Had to stop because the bolts that hold the stock lever on are not long enough. I thought they were standard 5/16" bolts, but they must be metric. The thread pattern matches a 1/4-20 bolt, but it is 5/16" diameter. Going to have to swing by the hardware store tomorrow to get new bolts. I also have to figure out how I will mount a shift ball to the top of it. I'll probably end up cutting the flat bar just above where the linkage connects to it, and welding on some of the same 1/2" tubing to the top that I used for the horizontal link, just to pretty it up some.

Here is the progress so far:

Comment